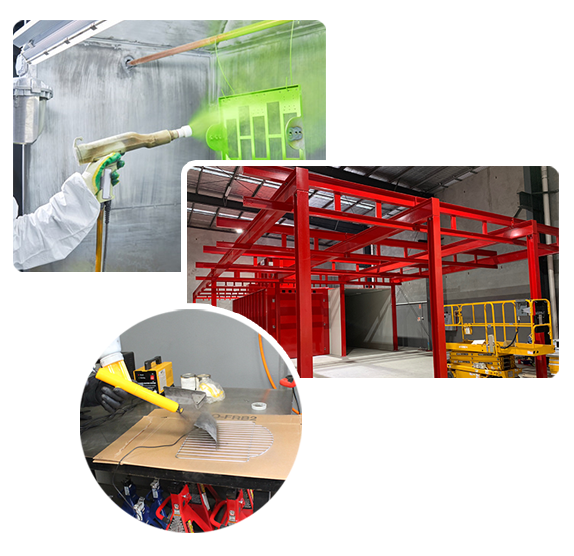

Powder Coating

When it comes to achieving an exceptionally durable and scratch-resistant surface for your metalwork, look no further than LPE. Our expert powder coating services provide a tough and long-lasting coating that resists chipping, ensuring your products maintain their pristine appearance over time.

Experience and Expertise

At LPE, we pride ourselves on our extensive experience in the industry. Our Operations Director brings over 25 years of expertise as both a fabricator and powder coater, enabling us to understand and cater to the specific needs of our customers. With our deep knowledge of the coating process, we can provide exceptional results that meet your exact requirements.

The Powder Coating Process

During the powder coating process, a finely ground powder is sprayed onto the item using a specialized gun. Electrostatic charges are applied to the powder particles, causing them to be attracted to the surface of the item. The coated item is then baked in an oven at a range of temperatures from 180 - 210C depending on material thickness and powder manufacturers specifications, allowing the powder to melt and form an even and consistently coloured finish.

Accurate Quotations

Our meticulous systems of work allow us to provide accurate job quotes by precisely measuring the areas to be coated. This not only ensures transparent pricing but also guarantees perfect continuity for repeat orders. You can rely on us to deliver reliable and cost-effective powder coating solutions.

Commitment to Quality

Quality is at the core of our operations. We maintain total traceability of all the powders used, ensuring the highest standards of performance and reliability. Our ISO9001-2008 certified total quality assurance systems ensure strict adherence to quality protocols. We conduct thorough in-process inspections at every stage of production to guarantee consistent excellence.

State-of-the-Art Facilities

Thanks to our cutting-edge powder coating plant, we have the capability to monitor substrate material temperatures closely. This enables us to ensure full curing and optimal adhesion of the powders, resulting in a superior and long-lasting finish. Additionally, our state-of-the-art phoswash automatic degreasing and pretreatment plant ensures thorough cleaning and the application of a phosphate coating. This enhances the longevity of the coated items and eliminates the risk of flash rusting prior to coating.

Capacity and Versatility

With our impressive 8m x 3m x 3m oven, we boast a larger capacity than any of our local competitors. This allows us to accommodate a wide range of projects, from small brackets to larger structural steel. Whatever the size or scale of your metalwork, we have the flexibility and resources to handle it efficiently and effectively.

Contact us today to request a quote and discover how LPE Group can be your trusted partner for all your engineering needs.

Request A Quote

Please fill out your details below and one of our friendly staff will get back to you